Industrial Real Estate Will Need More AI and Robotics: NAIOP

As the rapid growth in e-commerce continues to redefine last-mile delivery, new building uses and logistics technologies emerge.

Automation and the use of data analytics and artificial intelligence in industrial buildings—from megawarehouses to smaller, last-mile distribution providers—will grow, but human workers will still be needed to focus on creative problem solving, according to a report by the NAIOP Research Foundation.

READ ALSO: NAIOP CRE.Converge Spotlights Industry-Changing Trends

The 29-page report, “The Evolution of the Warehouse: Trends in Technology, Design, Development and Delivery,” by Steve Weikal, CRE Tech lead in the MIT Real Estate Innovation Lab, and James Robert Scott, lead researcher in the MIT Real Estate Innovation Lab, examines how these trends are affecting design and use of industrial buildings, and how new technologies can affect productivity and efficiency.

Driving the supply chain patterns is the rapid growth in e-commerce. The report notes the unprecedented demand is blurring boundaries between industrial and retail uses. For example, space in malls, shopping centers or individual retail locations can be used for distribution, which would help viability of some properties with reduced foot traffic and create advantages for retailers using hybrid distribution models.

Five retail properties in New Jersey and Connecticut owned by major mall and shopping center owners like Brookfield, Taubman and Macerich will be the first locations for ship-from-store service hubs for one company that converts empty spaces into micro distribution hubs for online fulfillments.

Walmart has increased its ship-from-store service to 2,400 sites and uses AI to manage purchases. Walmart has filed a patent for an automated system for storing inventory in the ceilings of superstores that employs a fleet of robotic vehicles to bring products down from the overhead space to the retail floor.

Walmart and Stop & Shop are also testing “dark stores” that are no longer used by in-store shoppers to do curbside pickup and delivery fulfillment at micro-fulfillment centers. Former shopping malls in several states including Ohio and Texas have been or are being redeveloped into warehouse distribution facilities.

Retail locations aren’t the only sites being repurposed for distribution and pickup locations. The report notes empty fast-food restaurants, parking garages and bank branches have been repurposed in some areas by companies like grocery operator Peapod, which is reconfiguring those types of spaces into remote grocery pickup locations.

In some cases, Peapod isn’t even using a physical building; the company is cross-docking vehicles to move products manually from one location to another so that the delivery fleet acts as a substitute for a warehouse. The report states at least one e-commerce software provider envisions a future of autonomous semitrucks that creates a network of moving warehouses and redefines last-mile delivery.

Walmart, along with Amazon and Target, is among the companies using more megawarehouses that often reach millions of square feet. They are usually highly automated but also need thousands of workers to store, package and ship goods. There is also renewed demand for older, smaller warehouses to serve as last-mile space close to major population centers. On smaller lots, developers are constructing multistory warehouses to take advantage of vertical space. Automatic storage and retrieval systems can help with flexibility in many of these locations.

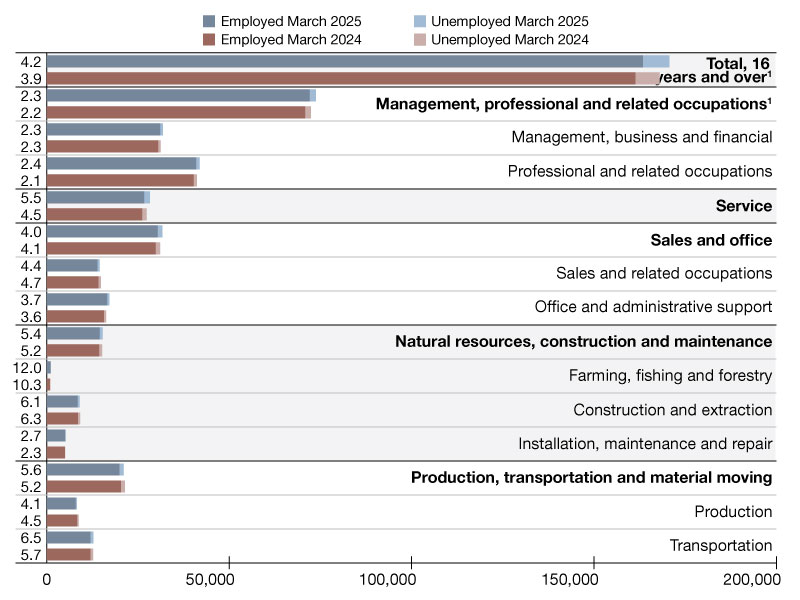

Steady growth

The use of commercial robots has been growing steadily, with more than 4 million expected to be installed in 50,000 warehouses by 2025, compared to 4,000 two years ago. Robots won’t all replace humans though. Many are designed to work with humans and make the warehouses safer and more productive. These days, they also help with social distancing to help reduce the spread of COVID-19 among workers. Automated guided vehicles and robotic carts are increasingly being used to move products around warehouses.

The report notes these trends will continue because they “can substantially increase a distribution facility’s throughput.” They will become more cost-effective, adaptive and productive as technologies improve, according to the authors.

In addition to increasing productivity and safety with robotics at individual sites, the report states data analytics and AI will increase efficiency across supply chains and the industrial real estate market.

“Data collected along the supply chain and from operations within logistics buildings will help developers make better locational decisions and improve facilities’ operational performance,” according to the NAIOP report.

Read the full report by NAIOP.

You must be logged in to post a comment.